Corrosion tests

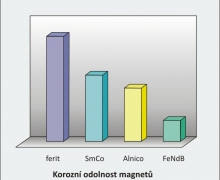

The various types of magnets significantly differ in their resistance to corrosion - see picture.

To improve the corrosion resistance especially of FeNdB magnets different finishes are used.

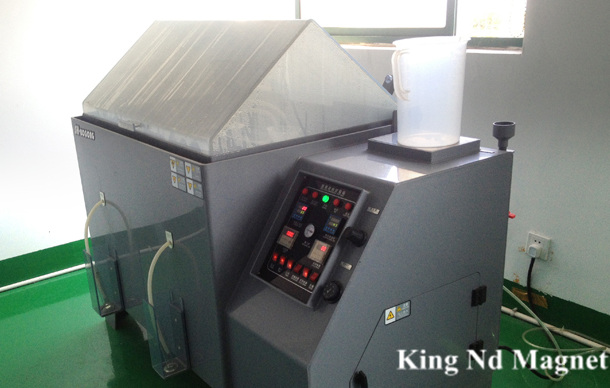

For testing the corrosion resistance there are two basic tests: salt spray (Salt Spray Test - ISO 9227:2006) and vapor pressure test (Pressure Cooker Test, Autoclave Test - IEC68-2-66). Tests are carried out in a closed corrosive chamber at the following conditions:

Salt spray test

Temperature: 35 oC (±2 oC)

Concentration: 5%±0.1% NaCl

pH: 6,6 – 7,2

Exposure time: 24 - 72 hours depending on the type of finish (see finish)

Evaluation criterion: Sample with no visible signs of corrosion

Test in a pressure steam

Temperature: 125°C (±5°C)

Relative humidity: 100 %

Pressure: 270 kPa (absolute)

Exposure time: 7 days

Evaluation criterion: Loss of sample up to 5 mg/cm2.