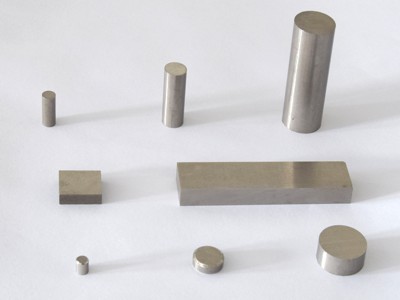

Magnets Alnico

Introduction

Alloy magnets on the basis of Al-Ni and Al-Ni-Co are material types with a long tradition. Although the sector of manufacturing advanced magnet types on the basis of rare earths is rapidly developing, alloy magnets continue to hold an important market share.

In the course of their development they made considerable advances in magnetic parameters – the manufacture of anisotropic variants, and shape requirements – application of precise casting methods.

Properties

Alnico magnets are manufactured using foundry technologies just like other special steels. The material is relatively hard. Its machining, except grinding, is very difficult.

After magnets of rare earths, Alnico magnets have the highest magnetic energy, coercivity and remanence. A high Curie temperature predetermines them for deployment at increased temperatures.

Applications

Alnico magnets are used in the following areas:

- electric motors of medium size,

- generators, loudspeakers,

- acoustic transducers,

- electrometers,

- electric measuring instruments,

- retaining industrial systems

Magnetic properties - Alnico

| Class | Coercivity | Remanence | Max. product | Curie temperature |

| HcB [kA/m] | Br [mT] | (BH)max [kJ/m3] | oC | |

| LNG12 1) | 45 | 720 | 12.4 | 810 |

| LNG 37 | 48 | 1200 | 37.0 | 860 |

| LNG 40 | 48 | 1250 | 40.0 | 860 |

| LNG 60 | 59 | 1350 | 60.0 | 860 |

| LNGT 32 | 100 | 800 | 32.0 | 860 |

| LNGT 40 | 110 | 800 | 40.0 | 860 |

| LNGT 60 | 110 | 900 | 60.0 | 860 |

| LNGT 72 | 112 | 1050 | 72.0 | 860 |

1) isotropic