Rubber magnets

Traditional materials for permanent magnets have some mechanical properties restricting their use: they are hard and generally brittle. This is due to the structure of magnetically hard materials in which it is necessary to form obstacles to the movement of the domain walls.

As a result, magnets need to be protected against physical impact and their machinability is very limited.

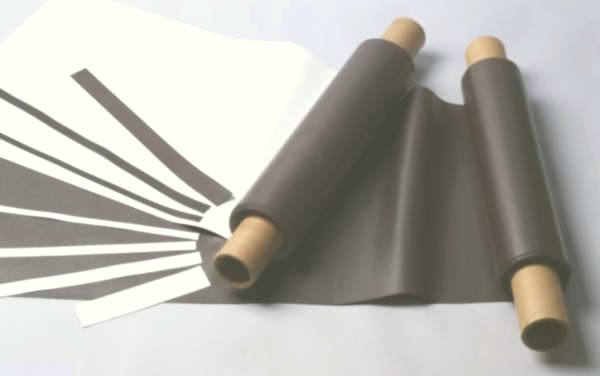

Practical requirements led to developing a magnetic material which is not brittle and is even elastic and flexible. Today it is called by the established term - magnetic rubber. It is manufactured from a fine powder of a magnetically hard material bound with an elastoplastic binder. The result resembles rubber of brown colour. The higher the content of the magnetic powder in the material the lower its elasticity and the greater its magnetic force.

Product range

It is manufactured in the form of thin foils from 0.3 to 4 mm thick, strips and belts, thicker plates and shaped profiles and products. The top surface may be finished by a coloured coating, mostly white, or a self-adhesive layer. Magnetisation can be of the dipole or multipole type just as with traditional permanent magnets.

Application

Magnetic rubber has been widely used in advertising and sign-marking (printing, signs, etc.), in the manufacture of holders of small souvenirs and in various industrial applications.

Table of properties – rubber magnets

| Class | Coercivity | Remanence | Max. product | Tensile strength | Stretching |

| HcB [kA/m] | Br [mT] | (BH)max [kJ/m3] | [ MPa ] | [ % ] | |

| NF04 | 80-104 | 140-160 | 3,2-4,8 | 6,0-8,5 | 80-100 |

| NF06 | 96-112 | 160-190 | 4,8-6,4 | 6,0-8,5 | 80-100 |

| NF07 | 104-135 | 190-220 | 6,4-8,0 | 6,0-8,5 | 75-90 |

| NF09 | 131-160 | 220-230 | 8,0-9,6 | 4,5-7,5 | 70-80 |

| NF10 | 151-167 | 230-240 | 9,6-10,8 | 4,0-7,0 | 60-70 |

| NF11 | 160-180 | 240-250 | 10,8-12,0 | 4,0-7,0 | 60-70 |